Hose Safety Restraints - prevent hazardous workplace incidents caused by hose coupling failure

Our hose safety restraints includes the classic spring wire hose whip checks, adjustable nylon hose restraints, our new hose cable chokers, and maximum security hose whip stop systems. An out-of-control pressurized hose can be hazardous to deadly. A properly secured hose will remain in place after failure, allowing for a quick and safe recovery. Reduce the risk of injury, widespread spills, downtime, and equipment damage by restraining all pressurized hose assemblies, large or small.

A hose is only properly secured if the restraint device is rated above assembly’s operating pressure. Standard hose safety whip checks are rated for 200 PSI air service. use a nylon hose whip restraint or a hose cable choker for higher pressure applications, and a hose whip stop system for the most severe or hazardous installations.

Be safe, always use a hose whip restraint to greatly reduce the hazard of a hose or coupling failure.

Nylon Adjustable Hose Whip Restraints

Nylon hose restraints are a light-weight, easy to install hose safety device, and are offered in a variety pressure ratings. From single ply to 4 ply, and an HD Gray version, there is a nylon restraint for just about any application. We can custom configure specific lengths or design with a hook or shackle for easy installation. Double restraint options (2 restraints sewn together) cover an even wider range of pressure ratings.

Hose Safety Cable Chokers

Cable Choker hose restraints are designed for applications exceeding the pressure rating of our standard hose whip check product line. The unique design allows the cable choker to cinch tighter around an unchecked hose. This not only holds the hose in place, but can also significantly decrease or stop flow completely until the pressure can be relieved. Hose safety cable chokers range from 3/32 cable up to 1/2 inch cable, covering hose sizes from 1/4 to 8 inch. Custom cables can be configured easily for a perfect fit.

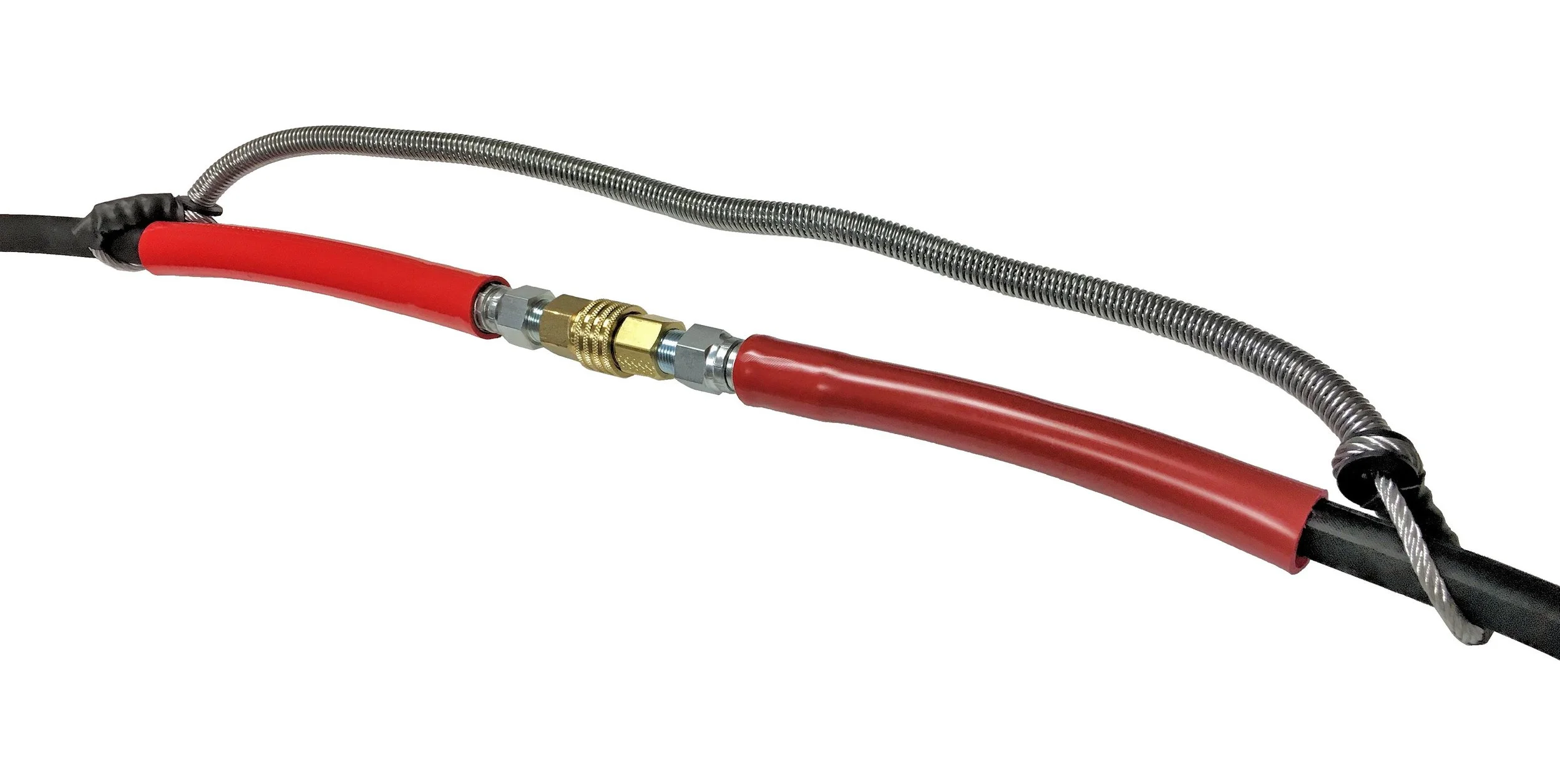

Whip Stop Braided High-Pressure Hose Restraints

Hose Whip Stops, also known as Whipsocks, are durable and secure restraints for high pressure applications where hose whip can be extremely dangerous. Offered in a variety of sizes, customizable to meet your requirements. Install using the hobble clamp (shown in red) or from one Whip Stop to the next when connecting hose assemblies to one another. Whip Stop restraints are best for assemblies that are not often disconnected.

Hose Safety Whip Check - the original air hose restraint

Hose Whipchecks are the standard in compressed air hose applications. Designed for 200 PSI air service with a 5X safety ratio, and in 4 different size ranges, the Whip Check is offers easy hose safety for most pneumatic tool applications. Available in hose-to-hose, and hose-to-tool connections for versatile installations.

Cam & Groove Safety Bump® Caps & Plugs

Safety Bump® caps and plugs are designed to fit any standard cam and groove coupling, and provide three safety features. First they prevent leaks from the hose during transport and storage, reducing slip and fall hazards and chemical or fuel spills. Second, the safety bump extends beyond the hose and coupling width, so when the hose is dropped, the Safety Bump cap takes the impact rather than the cam lock coupling. And finally, the over-sized handle gives the operator a secure lifting point to maneuver hose assemblies, reducing the risk of injury.

Offered in standard, anti-static, and food-grade white polypropylene

Safety Bump® and Safety Lock are registered trademarks of PT Coupling Company, all rights reserved

Hobble to Hobble Clamp Restraints

Hobble Clamp hose restraints clamp around a hose and bolt tight to more permanently attach a hose to pipe or to a weld point or flange.

These highly secure restraint assemblies are relied upon in the most severe service applications including offshore oil and gas.

Offered in clamp to clamp (as shown) which can also be two varying sizes of clamp, or clamp to anchor point (click link for more info).

Hobble clamps of varying size and style can be utilized to create a restraint for nearly any configuration. Also often used for securing 1502 pipe connections.

Steel cable link can be substituted with chain or stainless steel cable to meet the most challenging environments.

Air Tool Safety Check Valves (Pneumatic Hose Check Valves)

Hose Safety Check Valves are designed to cut off the air-flow on a pneumatic hose line if a surge in flow is detected which would indicate a hose or coupling failure. This device, when used properly, greatly reduces risk in the workplace by automatically turning off air flow before hoses have a chance to whip. Each size is available in a variety of preset SCFM cut-off rates for compatibility with most pneumatic tools. Install a safety check valve at the beginning of the pneumatic supply line (before any valve or quick coupling) and each branch line between the air source and the tool.

OSHA 29 CFR 1926.302(b) (7) and USBR 17.2.2 compliant

Secure-Lok® Lockout for Cam and Groove Couplings

Secure-Lock® adds a locking system to your cam and groove tank connections and hose assemblies. The 12-gauge 316 stainless steel hinged clamp encapsulates the cam arms so that they cannot be opened or tampered with. Protect petrochemical products from theft and vandalism. Reduce the risk of costly intentional and accidental spills. Use with lock-out tags to ensure that lockout instructions are followed.

2 inch through 5 inch diameter. Padlock not included.

Safety Bump® and Safety Lock are registered trademarks of PT Coupling Company, all rights reserved

The following are a list of known North American regulations regarding hose safety restraints and whip check devices.

Please check directly with all regulating agencies pertaining to your job site or workplace to verify the most up to date hose safety rules and regulations.

OSHA29 CFR 1926.603 paragraph (a)(10): Safety chains, or equivalent means, shall be provided for each hose connection to prevent the line from thrashing around in case the coupling becomes disconnected.

OSHA 29 CFR 1926.302(b) (1): Pneumatic power tools shall be secured to the hose or whip by some positive means to prevent the tool from becoming accidentally disconnected.

US Army Corps of Engineers 13.G.02: Connections and nozzles shall be designed to prevent accidental disengagement. All connections shall be equipped with safety lashings. 20.A.17 Connections with high pressure hoses must be secured with a safety lashing/whip check.

Canadian Centre for Occupational Health & Safety: Make sure that hose connections fit properly and are equipped with a mechanical means of securing the connection (e.g., chain, wire, or positive locking device).

MSHA 30 CFR §56/57.13021 High-pressure hose connections: Except where automatic shutoff valves are used, safety chains or other suitable locking devices shall be used at connections to machines of high-pressure hose lines of ¾-inch inside diameter or larger, and between high-pressure hose lines of ¾-inch inside diameter or larger, where a connection failure would create a hazard.

MSHA 30 CFR §75.1730 Compressed air; general; compressed air systems (e): Safety chains, suitable locking devices, or automatic cut-off valves shall be used at connections to machines of high-pressure hose lines of three-fourths of an inch inside diameter or larger, and between high-pressure hose lines of three-fourths of an inch inside diameter or larger, where a connection failure would create a hazard. For purposes of this paragraph, high-pressure means pressure of 100 p.s.i. or more.

United States Bureau of Reclamation 17.2.2 Air Hoses: For air lines more than one-half inch inside diameter, provide whip-check devices attached to the hose at each connection or splice. As a substitute, provide a safety device at the source of supply or branch line that will automatically reduce pressure in case of a line failure if the device effectively prevents whipping. (See Safety Check Valve product above)